14 October, 2008

category: Contactless, Financial, NFC, RFID

Jerry Banks, Co-author of RFID Applied

This article is based on a presentation made on June 5, 2008 at a kickoff meeting of a new RFID center. The author agreed to talk on the topic of recent advances in RFID. To accomplish the desired result, the RFID literature was monitored almost daily for the prior three months in search of advances in the technology.

First, we need to discuss what is and what is not an advance from the author’s perspective. Advances are hardware or applications that seem out of the ordinary. So, one person can read the report of some new tag and not be surprised, while another person will be surprised. Or, the reverse of that situation can occur.

Advances in tags

With respect to tags, the most surprising occurrence in the past few months was that Mojix unveiled the details of a customer field trial program involving more than a dozen companies utilizing its EPCglobal Gen2- and FCC-compliant STAR reader system, which can read passive RFID tags from distances up to 190 meters. Some of the features of the STAR reader system are as follows:

- 100,000 times the indoor receiver sensitivity of previous RFID solutions

- 20 times the read range of conventional passive RFID readers

- 100 times greater coverage than conventional systems

- Verification of 100 percent of tags on RF-challenged goods

- Non line-of-sight read capability

- One multi-purpose system to read, locate and secure RFID tag data.

When the notion of a passive RFID tag being read at a distance of 190 meters was put to one of my co-authors of RFID Applied, he called it “bogus.” That’s a colloquialism for “fake” or “untrue.” But, the Mojix system won ‘Best in Show’ at RFID Journal Live, held April 27-29, 2008 in Orlando, Florida. So, there must be something to it!

A popular tag is the Alien Squiggle. It has been mentioned in this series previously. We mentioned that it could be read at a distance of 19.4 meters in one test. So, you can see the relative difference in distances for a popular tag and for the Mojix system.

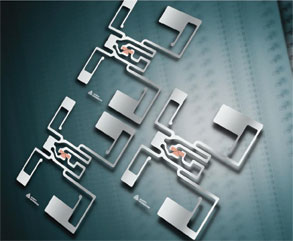

Recently, we were again experimenting with the Alien Squiggle tag. The best read occurred when the tag was perpendicular to the reader called ‘face-on,’ in this case the reader was a handheld Motorola device. The tag could not be read easily when it was on its side, or, ‘edge-on.’ But, the Avery Dennison AD-631 inlay is orientation insensitive, so it can be read in any direction (face-on or edge-on) which improves tag visibility in randomly oriented asset and pallet tracking applications. Avery Dennison says that the tag provides also a longer read range yielding greater readability rates.

Recently, we were again experimenting with the Alien Squiggle tag. The best read occurred when the tag was perpendicular to the reader called ‘face-on,’ in this case the reader was a handheld Motorola device. The tag could not be read easily when it was on its side, or, ‘edge-on.’ But, the Avery Dennison AD-631 inlay is orientation insensitive, so it can be read in any direction (face-on or edge-on) which improves tag visibility in randomly oriented asset and pallet tracking applications. Avery Dennison says that the tag provides also a longer read range yielding greater readability rates.

Another concern with tags is the amount of memory available. By the end of June 2008, Fujitsu announced that they would have a Gen2-standard RFID tag with 64 kilobytes of FRAM, which it claims is the highest-capacity Gen2 tag available. FRAM is Ferroelectric Random Access Memory (also referred to as FeRAM). FRAM uses ferroelectric film as a capacitor for storing data. Featuring advantages of both ROM and RAM devices, FRAM devices have high-speed access, low power consumption, and high endurance for numerous rewrites. Fujitsu is initially marketing the tag for aircraft maintenance applications.

Omni-ID now produces fully converted, ready-to-use RFID tags specially designed to perform well around liquids and metals. While an increasing number of tags have been introduced on the market that make the same claim, a key differentiator of Omni-ID’s QinetiQ tags is that they perform well when not around liquids and metals as well. The tag has a conductive substrate that creates an electromagnetic field around the chip when the tag is interrogated.

Omni-ID now produces fully converted, ready-to-use RFID tags specially designed to perform well around liquids and metals. While an increasing number of tags have been introduced on the market that make the same claim, a key differentiator of Omni-ID’s QinetiQ tags is that they perform well when not around liquids and metals as well. The tag has a conductive substrate that creates an electromagnetic field around the chip when the tag is interrogated.

In mid-February, 2008, STMicroelectronics announced that they had combined near field communications reading, processing, and memory functions into a single chip. The device has standardized NFC reading capabilities, 112 kilobytes of user ROM, 4 kilobytes of RAM, plus controller functionality and software in a single .13-micron chip that can function as both a reader and a tag. The product is intended for integration into cellular phone handsets and other devices. An example application is contactless payments.

Item-level tracking

We leave the discussion of tags to discuss item-level tracking, i.e. placing tags on every item. This is related to the section above, but we will return to that after we discuss this topic.

The concern about item-level tracking has been the cost of the tags. For example, is it a wise idea to put a $0.10 tag on a $0.90 can of beans? That excess can’t be justified. Somehow, merchants have found, or are investigating the, economic justification in placing tags on every item. The items mentioned are all worth more than a can of beans, and some of the examples are older than three months.

Beginning in May of 2008, retailer American Apparel rolled out an item-level RFID inventory tracking system in its 17 New York stores. The roll out will be complete in July 2008. The inventory process typically occupies four employees for eight hours. At the RFID-enabled Columbia University-area store, it takes two employees just two hours to take inventory. This savings from 32 person hours down to four person hours is in line with other reports that have been received.

As previously reported German department store operator, Karstadt, with 86 department stores and 32 sporting stores, tagged selected items of men’s apparel in a six-month pilot study that was launched in September of 2007. The tagged items were read at five points in the process:

- Upon receipt at the store

- Between the back room and the store floor

- On the shelves

- At the point-of-sale

- During inventory (by store staff using mobile readers).

Karstadt hopes that the pilot study will demonstrate:

- A dramatic reduction in the amount of time necessary to conduct store inventory

- Improved inventory accuracy, enabling misplaced items to be restocked faster

- Data about how often items are removed from their shelves

- Improved and automated shipment reporting, enabling errors to be discovered and corrected faster.

NP Collection from Finland expects full ROI in less than six months from a pilot program in which Gen2 tags were placed on 80,000 individual garments. The company plans to more than triple the number of garments tagged in 2008, add new inventory applications, and expand collaboration with suppliers and logistics providers.

METRO deployed an RFID system at their Galeria Kaufhof, high-end retail store, in Essen, Germany. It fully integrates many of the latest RFID retail applications including item-level tagging, supply chain visibility, back room inventory visibility, smart shelves, smart mirrors, point-of-sale information transfer and theft prevention. It is an end-to-end retail deployment all of which is based on Gen2 and related EPCglobal RFID standards.

As reported each individual package of fresh meat at the new METRO Future Store is labeled with a passive Gen2 RFID tag that keys applications to prevent the sale of outdated product and provide inventory information to drive replenishment and meat cutting operations.

Butchers at the store apply EPC Gen2 RFID smart labels to meat packages. Each package is identified and recorded when it is placed into the display case, which METRO calls the Smart Case. The implications for insuring the freshness of meat purchases and the taking of inventory with this system are vast.

Without going into detail on each of the latest RFID retail applications, we will discuss just one of them, smart mirrors. (Metro produced a “gee whiz” video in 2002 that showed how many of these applications would operate.)

Let’s say that a woman selects a black skirt and a white top, both RFID enabled, and takes it to a dressing room. She tries it on. She wonders how a purple top in the same style will work. She has logged her image into the mirror. Instead of changing back into her regular clothing, going out to find the purple top, returning to the dressing room (that could be occupied by someone else now!), and changing into the black skirt and purple top, she simply indicates that the mirror should reveal an image showing the black skirt and purple top. Voila! As if by magic, the image appears.

She can accept the combination (reject it, accept part of it, or, choose another combination) and the selected goods will be waiting for her at a designated location.

Organic ink

We are impressed with organic ink! We will be more impressed if it is implemented thereby saving much money for RFID tags. Parelec Inc. has developed ink chemistry that suspends the metallization in an organic carrier that decomposes after printing leaving a 99% pure metal coating. The company states that their organic ink is “3 to 10 times more conductive than polymer-based inks.”

We are impressed with organic ink! We will be more impressed if it is implemented thereby saving much money for RFID tags. Parelec Inc. has developed ink chemistry that suspends the metallization in an organic carrier that decomposes after printing leaving a 99% pure metal coating. The company states that their organic ink is “3 to 10 times more conductive than polymer-based inks.”

Kovio, a San Francisco firm, says that it expects to create printed-silicon high-frequency RFID chips by the end of 2008, paving the way to low-cost tags.

A*STAR Research, an institute sponsored by the government of Singapore, has developed capabilities in printed electronics. The Institute of Material and Research Engineering, a part of A*STAR Research, has received an injection of funding to further develop high performance functional materials for printed electronics such as semiconductors. SIMTech, another research institute sponsored by the government of Singapore, has developed capabilities in printing antennas for RFID tags. This is certainly an avenue for reducing the cost of tags.

In early March 2008, it was announced that a German government agency, the Federal Ministry of Education and five companies are jointly investing about $23.2 million in a three-year research project intended to develop better materials for printable RFID tags. The ministry provides almost half of the funds for the so-called MaDriX project with the remaining funds coming form German companies BASF, ELANTAS Beck, Evonik Industries, and Siemens.

Coradyn Biosystems is a smart sensor materials company developing responsive, conductive polymers for detecting biological and chemical analyses. In June 2008, the company announced licensing of responsive, conductive polymer technology from the University of Texas at Austin. Coradyn’s preliminary results support the potential for use in molecular sensing devices in a wide array of applications including RFID and wireless sensing.

Real-time Location Systems

Aeroscout announced a series of partnerships and new software capabilities that use multiple real-time location system (RTLS) technologies in a single system. The technologies are Wi-Fi based RTLS and ultra-wideband RTLS.

A new mobility initiative from Cisco Systems includes support for features that enable real-time location systems (RTLS) to go beyond just reporting location to include information about a tagged object’s work status, motion alerts, temperature, and input from other sensors. An application would be tracking infusion pumps in a hospital. The system would not only locate the infusion pumps (many do this already), but also determine if they are currently in use.

Securing RFID Systems

NeoCatena Networks plans to release a new product in June 2008 that will serve as a firewall to prevent fraudulent or malicious tag data from entering enterprise systems. The Silicon Valley startup was formed by a researcher who previously demonstrated that RFID passports could be cloned, and who maintains that most RFID systems used today are insecure. NeoCatena’s core preventive product is RF-Wall, a firewall-like appliance, which integrates transparently into a given RFID system right after the RFID reader and in front of the backend (Edge Server or middleware). RF-Wall analyzes tag data before it reaches the backend and can block the tag if it poses a threat or let it pass through if the tag data is safe.

Applications

Now, we note some new uses of RFID. These applications don’t necessarily use new technology; they just use existing technology in innovative ways.

Ford’s popular F-150 pickup trucks are now available with an RFID reader integrated in the bed to monitor cargo.

The Army is testing an RFID-based sensor system to record and store how often the cannons on M1 Abrams tanks are fired. The data will support proactive maintenance operations and help the Army determine when the barrels approach their end-of-life and should be replaced.

Engineers at Purdue University are creating a wireless implantable passive micro-dosimeter designed to be injected into tumors to tell physicians the precise dose of radiation received and locate the exact position of tumors during treatment. Clinical trials are scheduled for 2010.

Conclusion

RFID is advancing rapidly. As the literature is scanned, new items appear as if by magic. If this article is revised one year from today, its entire contents will be new.

This article is the tenth in an ongoing series that explains the principles of RFID. It was created for RFIDNews by Jerry Banks, Tecnológico de Monterrey, Monterrey, México. The author is one of four co-authors of RFID Applied, John Wiley, 2007, ISBN-10 0471793655; ISBN-13 978-041793656.