Card Tech 101: Advanced materials secure ID cards

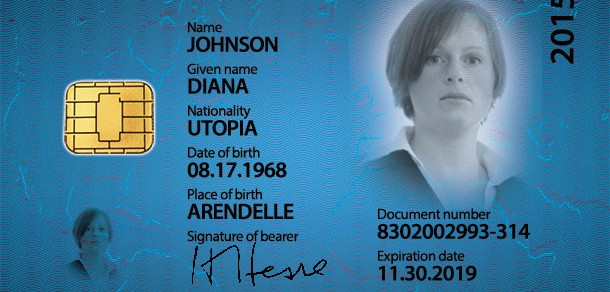

Fighting counterfeits, adding durability with composite cards

13 April, 2015

category: Contactless, Corporate, Financial, Government, Library, Smart Cards

Driver licenses nationwide go composite

MorphoTrust supplies driver license issuance materials and support to 42 states. According to Roland Fournier, senior marketing program manager at the company, states started moving to higher-durability, better security products about seven years ago because of REAL ID, a federal mandate to better secure state driver licenses.

“We’re seeing a variety of materials being used, with Teslin and polyester composites representing more than half the cards we issue,” says Fournier. Others use combinations of composite materials including polycarbonate and polyesters. He says only six or seven of their client jurisdictions are still using low-end PVC cards.

The combination of materials enables states to attain the durability of a 10-year document and add security features otherwise not possible such as laser engraving.

Selecting card materials based on issuance methods

To figure out which materials and security features work best, the first step is determining if issuance will be handled over the counter or through a central facility.

Over-the-counter issuance limits the security options to the time and ability of the desktop card printers. Central issuance gives issuers more options, including laser engraving, Fournier says. “You can use more sophisticated features when issuing from a factory,” he adds.

The composite combination of polyester and Teslin lends itself better to machine-readable technologies, Fourneir says. A handful of states still have magnetic stripes on their documents, which can place a strain on the document. In these cases, polyester composites are preferred because polycarbonate can crack with repeated swiping because the material is stiff. Thus they are not usually used with machine-readable technologies other than bar codes.

The type of card material used will determine the printing process as well, Fournier says. With the polyester and Teslin composite cards, the materials come to the central issuance facility in large sheets that will eventually become 12 individual IDs. Personalization is done on the Teslin layer, which is then fused with the polyester and then die cut into individual cards. These composite cards are also well suited to laser engraving, one of the more robust security features available.

In the past state driver license issuers have been reluctant to add to the cost of the cards. This has changed in the past few years, as states recognized the need to do more to stymie counterfeiters, Fourneir says. In the past the DMVs were profit centers for states, he notes, so they were incented to keep costs down.

“But we have seen more sophisticated card materials being used, as well as a willingness to spend more on securing the card to stay ahead of the counterfeiters,” he explains.

MorphoTrust states are spending between 75 cents and $1.10 per card, Fourneir says. States are also making sure they use multiple security features on the credentials in an effort to thwart counterfeiters.

“Issuers are selecting card materials that can enable multiple ways of personalizing,” he says. “Laser engraving, laser ablation and variable ultra violet in different colors are all methods of personalization that increase the difficulty of counterfeiting. If a counterfeiter has to master 34 different personalization techniques, that gets it out of the hands of the everyday fraudster and makes it more expensive,” he explains.

Issuers are selecting card materials that can enable multiple ways of personalizing. Laser engraving, laser ablation and variable ultra violet in different colors are all methods that increase the difficulty of counterfeiting

Some of the visual security features that issuers regularly use come from ITW Security and Brand Identity Group. The company makes products that work with all types of cards including composites, says Joanne Ogden, global sales manager for the security division at ITW.

ITW’s Covid and Fasver products are overlays that increase security and deter fraud. Covid places holographic images on top of the printed elements of the card, while Fasver enables visible and invisible printed elements to be integrated.

When a new customer begins to work with ITW the company looks at the equipment the issuer has and security features that work with the existing equipment, Ogden says. Typically Covid is used with PVC materials, while Fasver is ideal with Teslin, polycarbonate and other composite cards. “We work with a range of products, no one material is prevalent,” she explains. “PVC is the age-old material, but we’re seeing more and more Teslin and polycarbonate.”

For many, cost is the biggest detractor to using some of these new materials. Laser engraving can add tens if not hundreds of thousands of dollars in additional cost to a project, Ogden says. “Finished cost of a polycarbonate card can be three times that of a PVC card,” she explains.

A composite future?

Still when it comes to security and combatting counterfeiters, it could be money well spent. The only way to make visual inspection work is to ensure the ID documents cannot be easily forged. Card construction, materials and the visual security features they afford are key to this process.

National IDs, driver licenses and other government identification are often the cards using these materials today. Other issuers haven not yet shown significant interest in more secure, non-PVC card materials, Fourneir admits. “We’re not yet seeing widespread adoption of the advanced materials in the corporate space,” he says.

But there are signs that this is changing.

As U.S. banks add technologies to cards because of the switch to EMV, they are showing more interest to both protect the card and add longevity by increasing durability, Fourneir adds. Other issuers from corporations to educational institutions are feeling the fraud pinch as well, and it is inevitable that the threat will rise. But as education about the countermeasures offered by advanced materials spreads, the cost benefit balance swings in favor of better security.