Card Tech 101: Advanced materials secure ID cards

Fighting counterfeits, adding durability with composite cards

13 April, 2015

category: Contactless, Corporate, Financial, Government, Library, Smart Cards

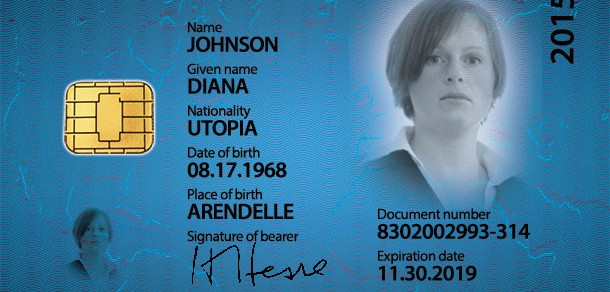

Identity can be asserted in many different ways. Tapping cards for access or inserting one into a reader to encrypt an email are just a couple examples. But still the most common way an individual asserts an identity is by handing an identity document to someone for visual inspection. The inspector compares the person to the picture on the card, verifies other data and then makes a determination.

Even in this overly electronic world, the vast majority of identity documents are visually scanned before access is granted. Whether going through security at the airport, verifying age at a bar or visiting an office building, it’s likely that an ID will be inspected.

The problem is that visual inspection only works if the ID document can be trusted. If cards can be readily counterfeited, the system breaks down rapidly. And as the volume of fake driver licenses and identity documents shipped in from overseas, made in garages or dorm rooms increases, steps need to be taken to thwart counterfeiters.

This means issuers need to take steps to ensure that their documents are counterfeit resistant. The materials that make up the card, its construction and personalization should all be carefully evaluated and selected to maximize security and durability.

High-security issuers are already recognizing the need and securing their card construction and materials, but other issuers need to take notice. Experts agree the threat will only continue to rise and broaden in the coming years.

Building a plastic card

Many assume the standard CR80-sized plastic card is a single piece of plastic die cut from a large sheet, but the truth is a bit different, says Pierre Scaglia, global segment manager for Secure Credentials at PPG Industries.

A typical card includes multiple layers of white plastic made from polyvinyl chloride (PVC) with a clear PVC layer on top. The clear layer contains the variable information, such as photo and demographic information. The card can also include an overlay or laminate layer with a security element such as a hologram that is added during the personalization process.

If the card includes electronics – such as a contactless chip and antenna array – those are sealed in a sheet of plastic and placed in between the PVC core layers, Scaglia explains.

Common cards, commonly counterfeited

“This basic PVC card offers fairly low levels of security,” he says. This alludes to the fact that it can be easily and inexpensively counterfeited.

PVC cards are everywhere, likely due to their extremely low cost. They are personalized using readily available desktop printers. These printers as well as the PVC cards and printer ribbons are available online from countless resellers and auction sites.

This makes them great for fast, convenient and low cost ID creation. But it also makes them extremely susceptible to fraud.

Composite materials turn the tide on fraud

Instead of constructing cards with layers of PVC, composite cards layer different materials to add advanced features and combat counterfeiters. Composites are the go to options in the high-security identity document market.

One common composite is a Teslin core with two polyester overlays, Scaglia says.

Teslin is a substrate material, manufactured by PPG Industries, which is placed in the core of a card and then personalized with photos and other information. The Teslin substrate absorbs the printing and lamination materials making it resistant to de-lamination and altering. It also increases the durability of the card and adds cushion to better protect chips, antennae and other embedded electronics.

Teslin also enables the issuer to embed other security elements into substrates of the card, Scaglia explains. “There are a range of Teslin substrates that incorporate different security features such as ultra violet or forensic features,” he adds.

The Teslin core is typically surrounded by polyester overlays, which protect the card. The three sections are bonded together using a thermal adhesive, Scaglia explains. “The advantages of this construction are that you secure the information into the substrate and once it’s there it can’t be altered,” he adds.

This type of card also has far greater durability than a typical PVC card. A bend test of durability found that the composite card will last 300,000 bend cycles, whereas a PVC card lasts between 16,000 and 20,000, Scaglia says.